How We Use Screen Printing to Make Enamel Pins Pop

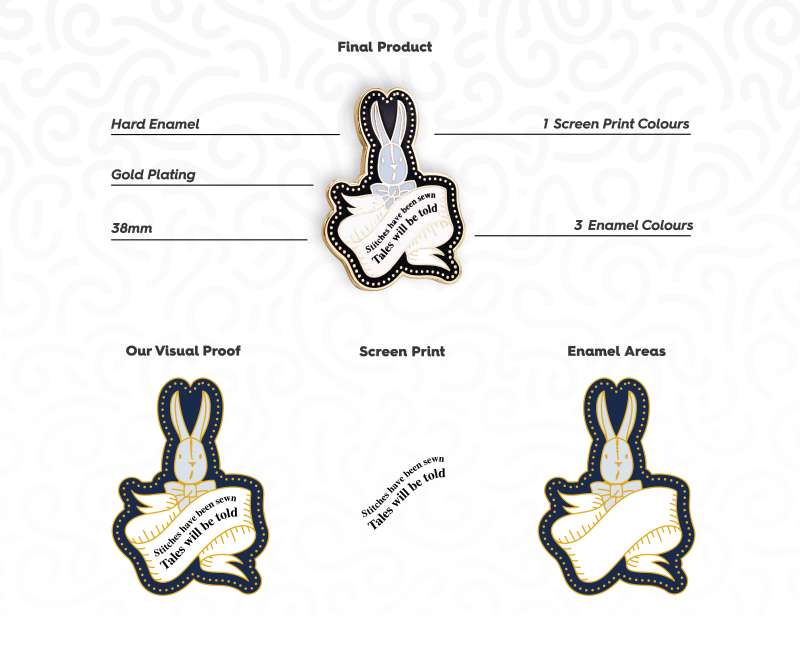

Whether you're a designer, marketer, or work for a charity organisation, as a maker of enamel pins, standing out in a sea of competition is critical. One way to make your pins pop is to use screen printing to add intricate details that are impossible in soft or hard enamel.

In this article, we'll show you how some of our clients have incorporated screen printing to enhance their enamel pins and attract more customers.

What is Screen Printing?

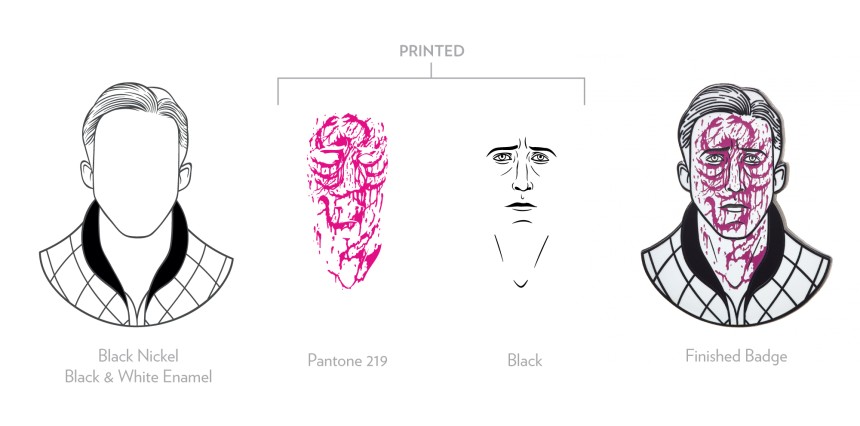

Screen printing is a technique that uses a mesh screen to transfer ink onto a surface. It's commonly used for printing on t-shirts, but we can use it on enamel pins to make them pop. The process involves creating a stencil on the screen and then placing it on top of the pin, and ink is pushed through the screen onto the pin.

What is Pad Printing?

We'll use pad printing to transfer the parts of your design that are too small for enamel onto a pin badge using a silicone pad.

The pad transfers the ink to the badge by pressing it down on the item, leaving the ink in the desired place. We'll use the best method based on your design, colours and other factors to ensure we recreate your design as faithfully as possible.

Benefits of Screen Printing for Enamel Pins

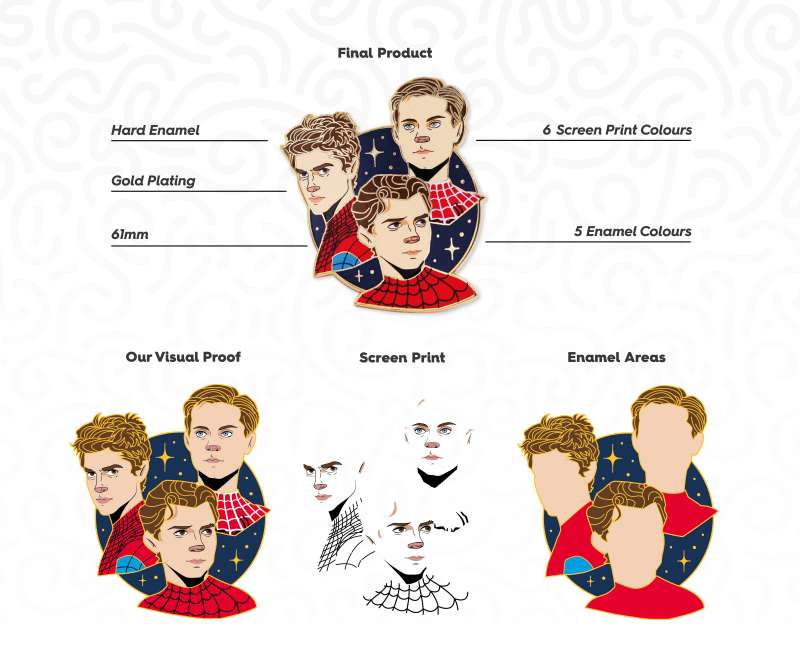

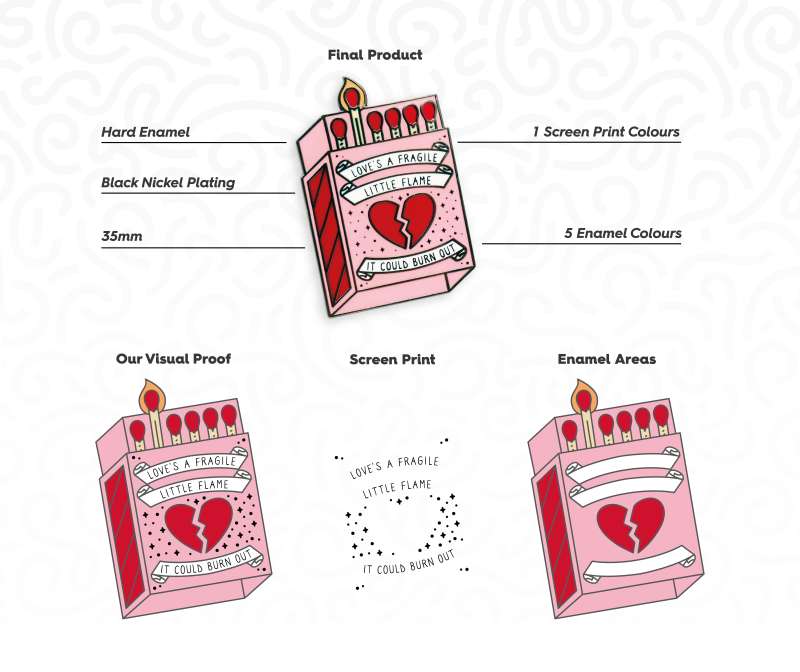

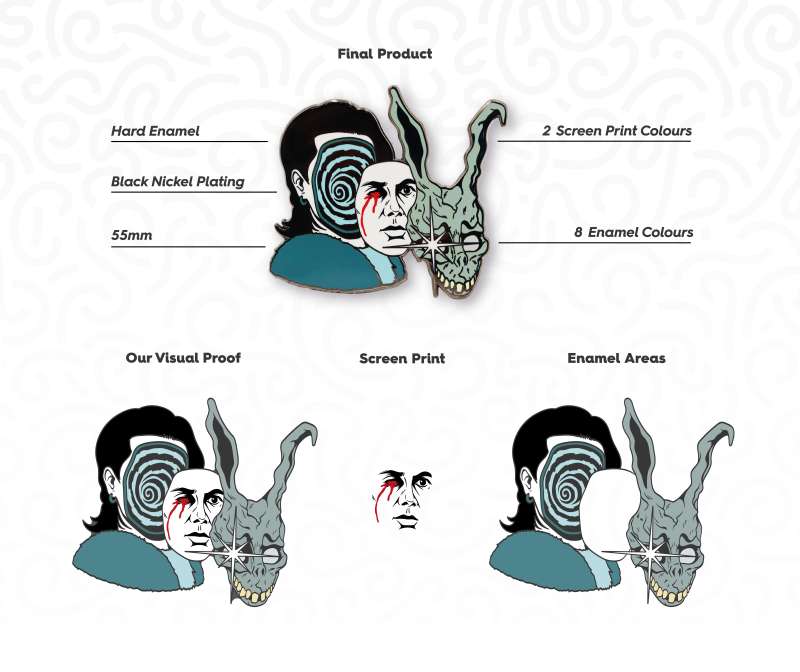

Screen printing offers several benefits when it comes to creating enamel pins. First, it allows us to create more intricate and detailed designs and turn them into pins. We can do this because the screen can be made with very fine lines and details, resulting in a high-quality print.

Additionally, screen printing allows us to use a broader range of colours, making creating vibrant and eye-catching designs easier.

Print durability is another benefit of screen printing, providing more value to your pins. The ink we use when screen printing is more resistant to wear and tear, making it ideal for pins that will be worn and displayed frequently.

What are the Limitations of Screen Printing?

Screen printing can add some extra 'pop' to your pins; there are a couple of things you should know to ensure your design comes out exactly as you hoped.

While we can screen print soft enamel badges, you will need to choose an epoxy coating for your pin so that we'll have a flat surface to print on.

Additionally, if you're designing a hard enamel pin, we advise not to include screen printing that overlaps areas of enamel and metal. While hard enamel pins have a flatter surface than soft enamel, there will still be some small ridges that could distort the print and make the finished product look a little off-kilter.

And nobody wants that!

Key Takeaways

Screen printing is a valuable tool for creating eye-catching and durable enamel pins. By using this technique, we have been able to make our pins stand out and attract more customers. Consider incorporating screen printing into your enamel pin-making process to take your designs to the next level.

If you've got some pin badge ideas you think might need screen printing, get in touch, and we'll advise you on the best processes to bring your badges to life.