What’s The Difference? Soft Enamel vs Hard Enamel Pins

Soft and hard enamel pin badges are among our most popular products, and our design and manufacturing expertise ensure they are of the highest quality.

Though hard enamel and soft enamel pins might look similar on the surface, they are two distinctly different products. Choosing the right one is not just a choice; it's a decision that could be the difference between a nice badge and a truly epic one.

So, how do you choose one product over the other?

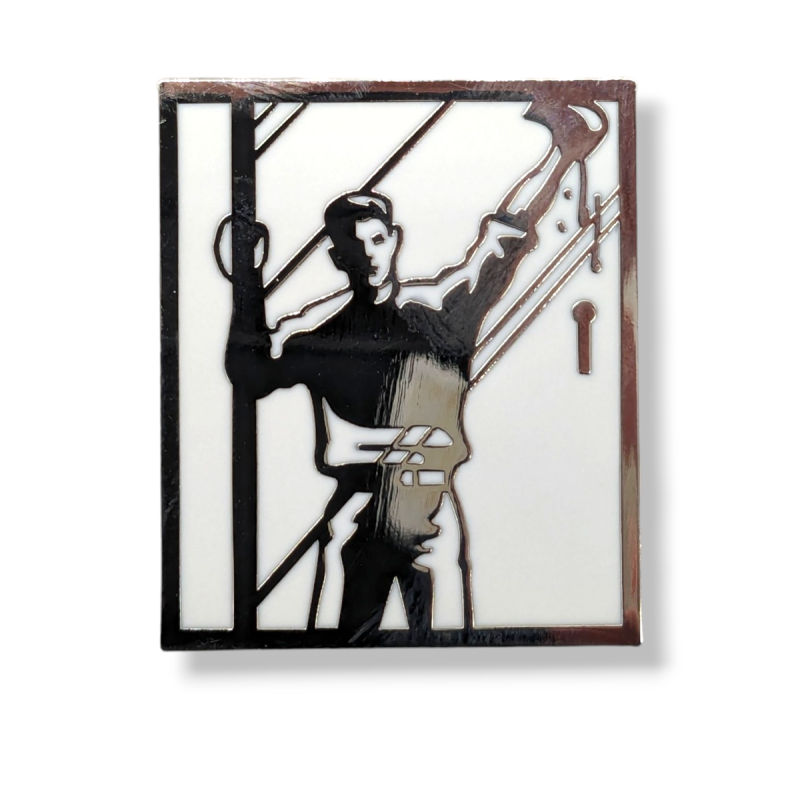

Here's a short Instagram video explaining the differences, followed by our written explanation about the subtle differences between hard and soft enamel pins.

What is Soft Enamel?

After we create the mould of your design, we stamp it into a metal base and cut it to your required size. With the pin's base ready, we'll coat it with the desired plating (here's what plating is and why you need it), add the different-coloured enamels to the recessed areas, and bake at sweltering temperatures until the enamel hardens.

During the baking process, the enamel paint will adhere to the plating. The die lines keep the colours separate, and because we don't completely fill the recessed areas, the soft enamel pin badge will have a textured or bumpy feel.

Because we make soft enamel badges in the way, we can add more detail to designs than we can with hard enamel pins.

What is Hard Enamel?

The initial manufacturing process of hard enamel badges is exactly the same until we reach the plating/enamel stage, at which point things take a drastic chance.

Unlike soft enamel, we add the enamel paint to the base BEFORE we plate the pin badges. We fill each recessed area with enamel paint to the top before baking, and we bake the badges one colour at a time, which is why hard enamel badges are marginally more expensive and why they take longer to make.

After each baking, we'll polish the badge flat so the edges are nice and smooth. When all the colours have been added, we electroplate the base and polish it one more time. Because hard enamel pins are polished so many times, the die lines can spread slightly, giving them a thicker appearance. This is why this product can't incorporate small details in the same way soft enamel can. However, this process makes hard enamel the perfect choice for crisp and bold designs.

Our hard enamel process is a contemporary take on the traditional hard enamel badge process. The key distinction lies in the enamel itself; unlike traditional hard enamel, which uses glass-based enamels that cannot achieve Pantone matching and have a higher pigment content, our hard enamels offer a different composition.

What if I Like the Fine Details of Soft Enamel and the Smooth Finish of Hard Enamel?

Then you're in luck.

We can apply an epoxy resin coating to soft enamel pins, giving them a super-smooth surface without losing any intricate details. While the coating will give these badges a hard enamel appearance, they are still soft enamel at the core.

Any Further Questions About Soft and Hard Enamel?

If you need further information about these fantastic products, send our expert team a message, and we'll provide you with all the information you need to make the right choice for your design.