Why Does It Take So Long To Make Enamel Pins?

Making enamel pins is addictive, especially if you're the creative type.

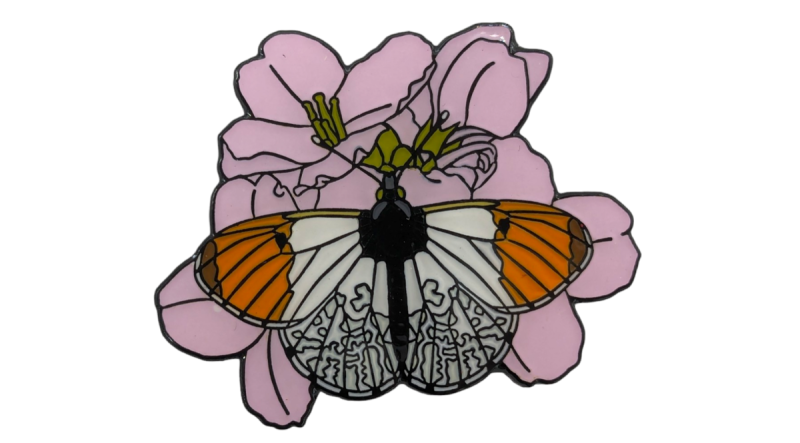

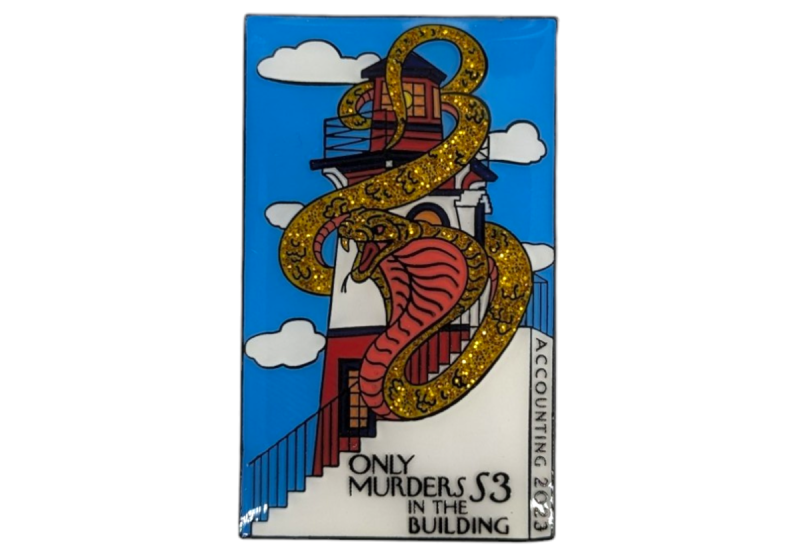

There's nothing like opening a fresh batch of badges you've designed and feeling the cold, smooth metal in your hands. Your digital image transformed into vibrant, tangible products.

However, it can seemingly take a lifetime from placing the order to your badges landing on your doorstep.

So, why does it take so long to make enamel pins?

Understanding the process and what goes into the production time can shed light on the timeline from design to delivery and maybe give you a newfound respect for the craft.

How Long Does It Takes To Make Pin Badges?

Three to four weeks is the typical answer. However, the specific timeline from placing an order to delivery depends on how quickly the visuals are signed off, the complexity of the badges, and the order size.

If you sell pin badges for a living, you'll probably be eager to get your next batch as quickly as possible. We offer an Express Service that will significantly speed up the process.

Understanding Enamel Pin Production

High-quality enamel pins are the result of a meticulous manufacturing process that combines modern technology with traditional craftsmanship. For a brief overview of what it takes to create a batch of enamel pins, check out our Instagram reel.

Here's a more detailed look at the steps that contribute to the overall order time.

Design and Proofing

The design phase is crucial before any physical production begins. Artists and manufacturers work together to ensure the pin's design is not only aesthetically pleasing but also suitable for production. Designing badges involves multiple revisions and proofing stages, where every detail must be perfect, from colour to line thickness. The proofing process can take several days, depending on the complexity and revision requests.

Our expert team offers a free design service to ensure your ideas are transformed into production-ready visuals as swiftly as possible without compromising quality.

Mould Creation

Once the design is finalised, we need to craft the unique custom mould. This mould is essential for casting the pins in the correct shape and requires precise engineering. Creating the mould is a meticulous task, but it's time well spent as any repeat orders will use the original mould, enabling us to cut production time on the second order and offer our Encore discount.

Stamping and Outlining

The metal bases of enamel pins are stamped using the custom mould. This step is relatively quick, but each pin must be individually stamped, which can add up when dealing with large orders.

Adding Colour

After stamping, the pins are hand-colored. Enamel is carefully applied to the recessed areas of each pin, a process known as filling. Depending on the number of colours and the complexity of the design, this can be time-consuming, but the skill of our factory workers is exemplary.

Firing and Polishing

Each pin is then fired in a kiln to harden the enamel. The high temperatures solidify the colour, ensuring durability and the glossy finish that enamel pins are known for. After firing, each pin is polished to remove imperfections and give it a smooth surface. This process is critical to the final quality of the pin.

Quality Control and Packaging

Quality control is an essential final step. Each pin is inspected for defects; sometimes, pins must be redone if they don't meet the standards. This can add to the production time, especially for larger orders. After passing quality control, pins are packaged and prepared for shipping.

The Reality of Enamel Pin Production Time

The timeline for creating enamel pins can vary significantly based on order size, design complexity, and workload. On average, the production time will range from around three to four weeks. While it may seem like a lengthy process, the time invested ensures that each pin meets quality standards and fulfils the design's vision.

In conclusion, the production time for enamel pins is influenced by several factors that involve careful attention to detail and craftsmanship. While it may require patience, the end product is worth the wait for a custom piece that can be treasured for years to come. These processes should explain why pin badges are the price they are, too.

If you plan to order custom enamel pins, account for these production times to avoid missing your deadlines. Contact us today to get started.