What’s the Difference Between Overlocked and Heat Cut Patches?

When you're designing custom patches, understanding the different edge treatments can make all the difference in creating an eye-catching product.

Two of the methods we use for finishing the edges of patches are overlocking and heat cutting. Each has its own unique advantages, and choosing the right one can depend on your specific needs and preferences.

So, let's check out the difference between overlocked and heat-cut patches to help you make an informed decision.

What Are Overlocked Patches?

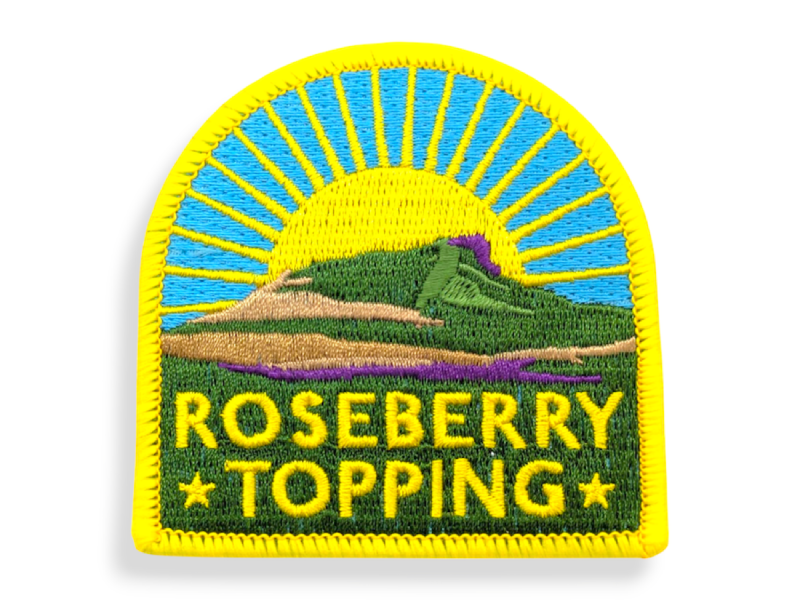

Patches with overlocked edges, also known as merrowed edge patches, are characterised by a thick, colourful thread that wraps around the edge of the patch. This technique involves stitching over the edge of the patch fabric, creating a raised, defined border.

Advantages of Overlocked Patches

- Durability: The overlocking process adds extra strength to the patch, making it more durable and resistant to fraying.

- Classic Appearance: Overlocked edges give patches a traditional, polished look that many people prefer for uniforms and classic designs.

- Thickness: The thickness of the edge makes the patch stand out, which can be visually appealing.

Overlocked Borders - Ideal Uses

Overlocked patches are ideal for traditional designs that require durability and a classic appearance. They are commonly used for military uniforms, outdoor activity badges, and sports team logos.

What Are Heat Cut Patches?

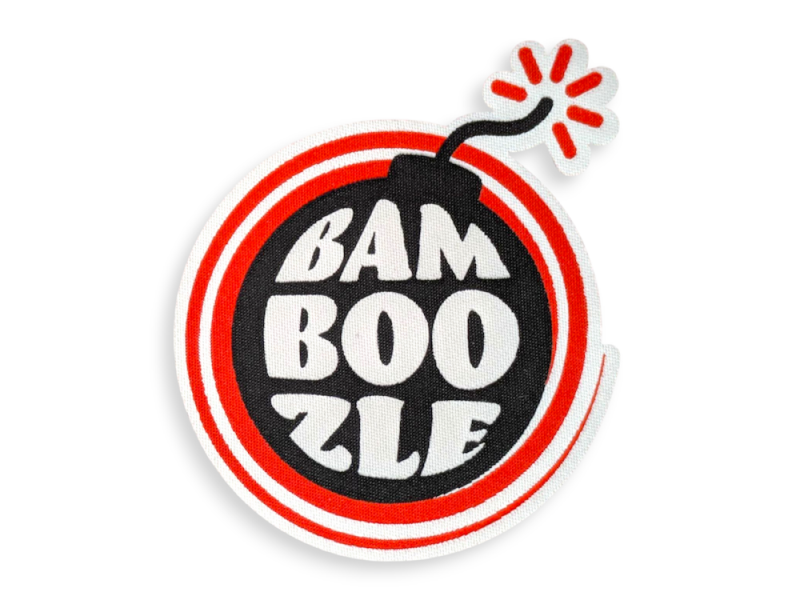

Heat-cut patches, also known as laser-cut patches, use a hot knife or laser to cut the patch fabric, resulting in a clean, sealed edge. This method prevents fraying and enables the creation of more intricate patch shapes.

Advantages of Heat Cut Patches

- Precision: The heat-cutting process enables precise cuts, allowing for the creation of patches with intricate shapes and designs.

- Sleek Look: Heat-cut edges provide a smooth, seamless finish that is ideal for modern and detailed designs.

- Flexibility: This method is well-suited for patches with complex shapes or non-standard sizes.

Heat Cut Borders - Ideal Uses

Heat-cut patches are ideal for contemporary designs that require precision and a sleek appearance. They are often used for corporate logos, fashion brands, and promotional items.

Do Borders Affect The Types of Patches & Backing I Can Choose?

A tiny bit. Here's our list of custom patch products you can create with us.

The only product for which you cannot choose laser-cut or merrowed edges is our custom rubber patches (for obvious reasons). You can, however, select any of our patch backings with both heat-cut and overlocked patches.

Making the Right Choice For Your Patches

Choosing between overlocked and heat-cut patches largely depends on the intended use and desired appearance of the patch.

If you value durability and a classic look, overlocked patches may be the way to go. However, if you are looking for precision and a modern aesthetic, heat-cut patches are likely the better option. Understanding the difference between overlocked and heat-cut patches can significantly influence your customisation choices. Evaluate the specific needs of your project and choose the edge treatment that aligns with your design goals.

When you've chosen your patch design and selected your preferred border, contact our friendly sales team, and we'll get your order underway.